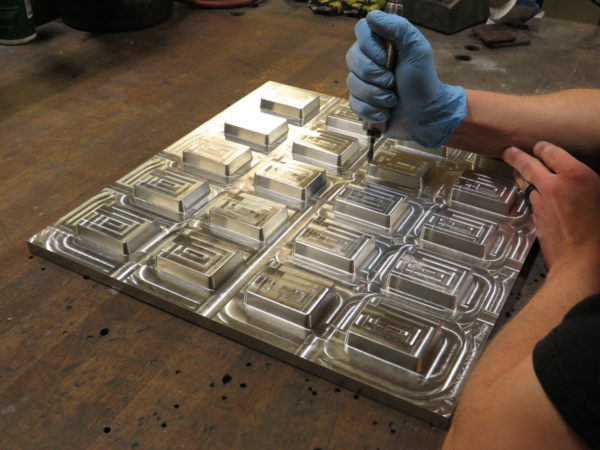

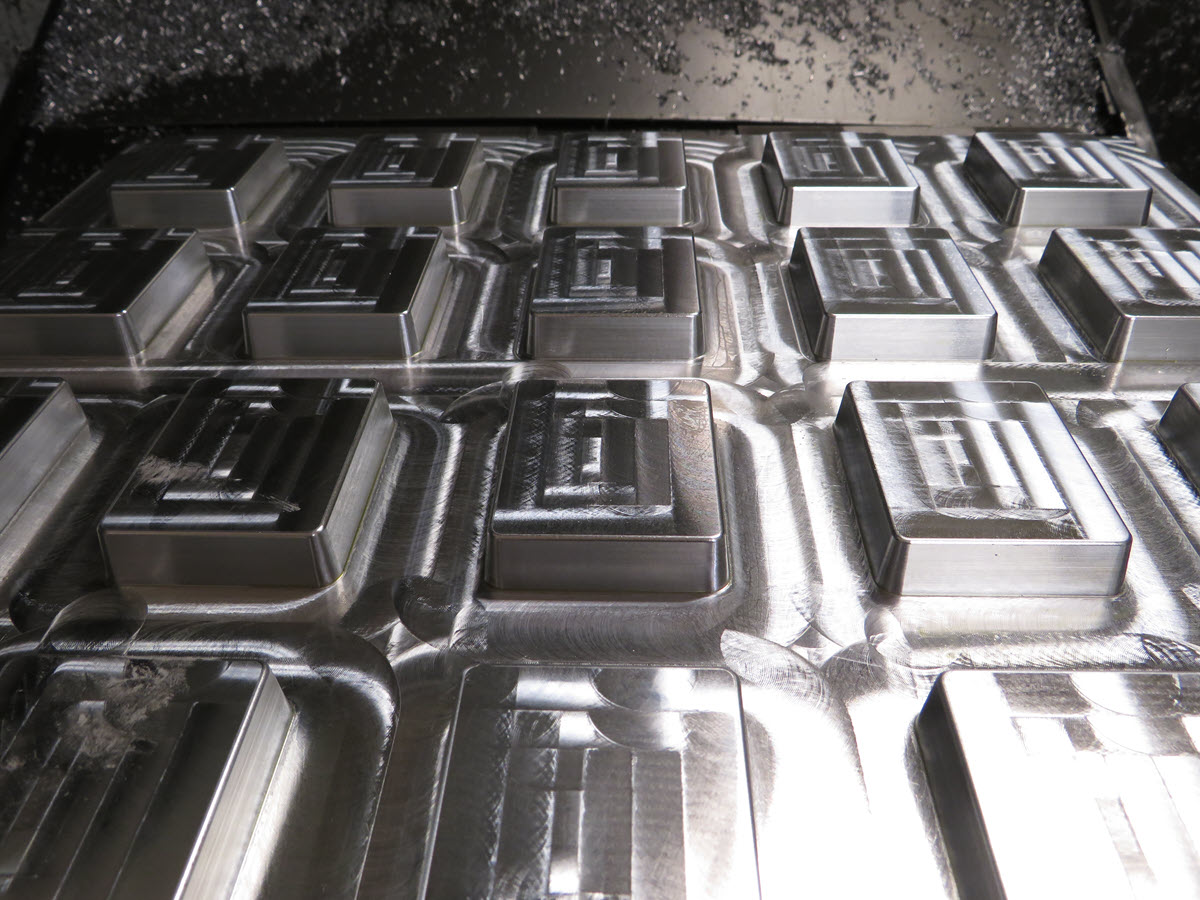

Our team of expert tool makers with over 35 years of mold making experience use modern state of the art CNC machining centers along with proprietary tooling processes that allow for quality parts being manufactured efficiently and on time.

All molds are created to run on our proprietary, high speed inline equipment.

Because all design and tooling is done in house, under one roof, we have complete control over strict proprietary manufacturing processes. This allows complete control from design to manufacturing, greater accuracy, and the flexibility needed to identify issues and correct them quickly.

In-House Tooling Means

- Better delivery

- Competitive pricing

- Fast Delivery

- Greater flexibility