Every custom package begins in our design department. Our extensive thermoform packaging design experience allows us the knowledge necessary to design cost effective packaging solutions.

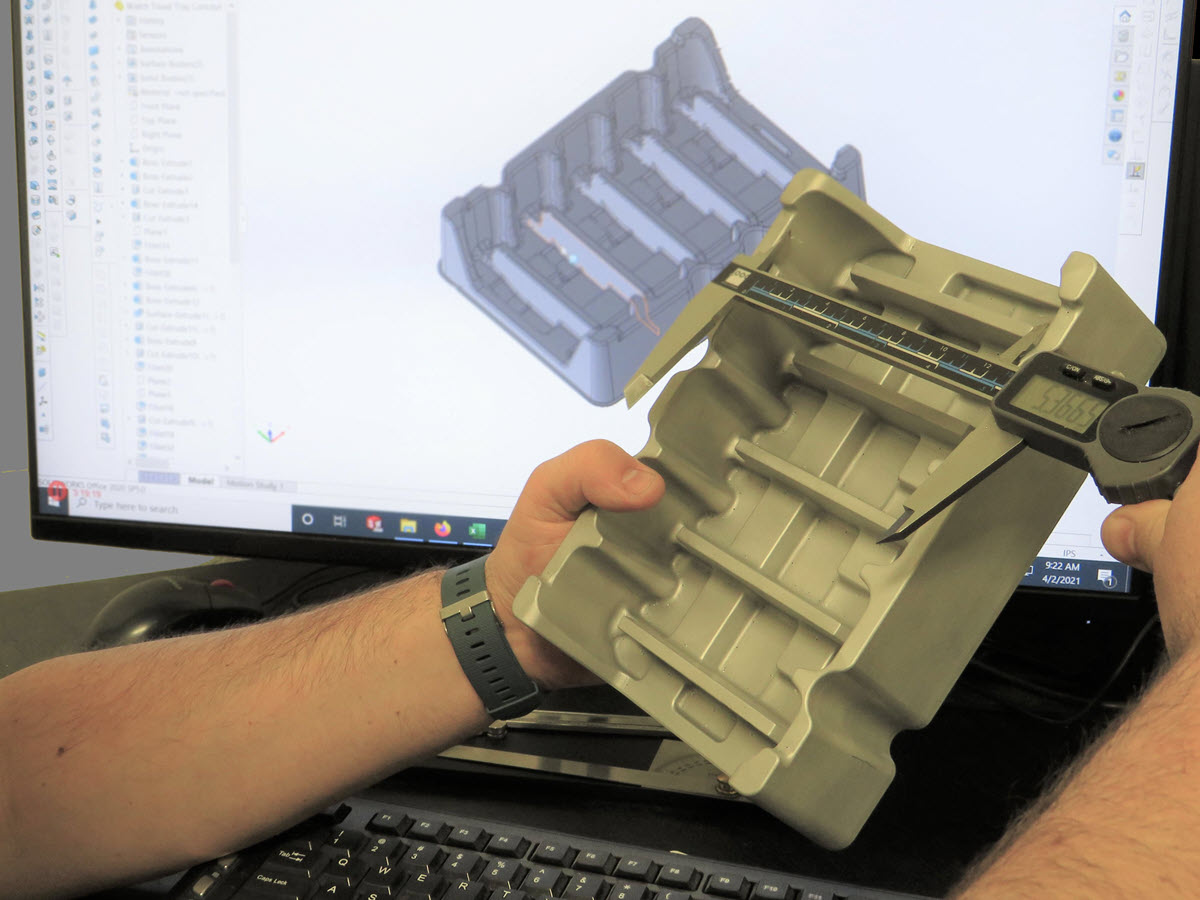

We utilize the latest high tech Computer Aided Design (CAD) software’s coupled with proprietary in-house systems to design packages that are thermoforming friendly.

Because design and tooling manufacturing are done under one roof, our design team will ensure designs meet the standards and requirements required for accurate and reliable manufacturing.